Ordering and evaluating product samples from a manufacturer is a great way to determine the quality of the product before you make a purchase order. This step comes after sourcing and before initial production. It would help if you made sure that the product samples match your expectations of the final goods, as manufacturers will be used the samples as a benchmark when it goes into production.

The next step is ordering product samples when you find a suitable supplier with a decent quote. This is a crucial step before you begin production to ensure that the supplier is legit and will make your product exactly the way you want. We created this guide to go over everything you need about samples. We’ll cover the types of samples and best practices and share several great tips.

Why should you order product samples?

Ordering product samples before you make a purchase order is an essential step. In most cases, this will be the first time you see your product. Here are the main reasons for ordering product samples:

- Make sure that the supplier is legit.

- If you are ordering a customized product, it is essential to see how the product looks before a production run

- Check to see how the product will look before production

- Make sure the manufacturer is capable of making your product

- It would help if you never trusted the supplier to say they can make it, and you need to have them produced.

Common types of Product Samples

There are a few different types of samples that you should expect to receive depending on your product.

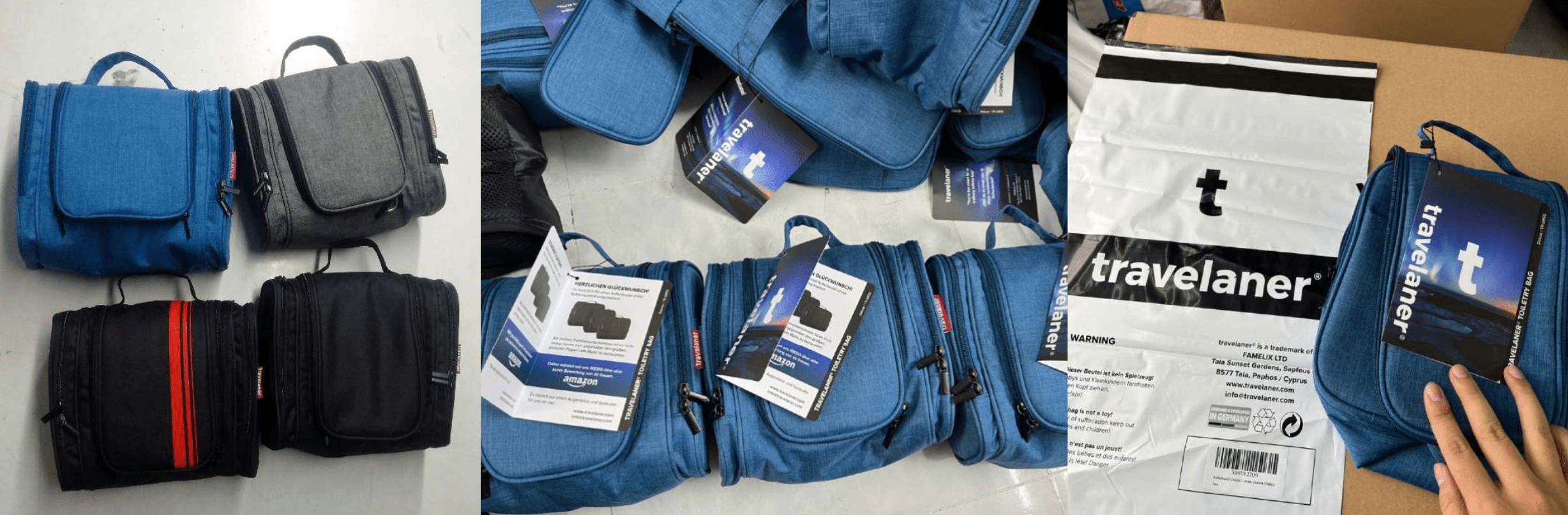

Off-the-Shelf Samples – These are the most basic product samples that you can get and are a product they have made that they have pulled off a shelf or from their warehouse. These typically have little to no customizations. Be careful with these as a trading company, posing as a factory, could have bought it from a store.

Material samples – These are not finished goods but are samples of materials they can use in the product. Common examples of this are different types of woods and finishes.

Customized Factory sample – If you are doing private or white-label products with minimal modification, you will order a pre-made sample that the factory has on hand. The factory often remakes these, but if you are getting some customizations, then it will take time to produce.

Production Sample – these are made on the actual production line as close, if not exact, as possible to your specifications. These will also use the same methods used in production; in some cases, the factory will document the steps for your reference.

Randomly selected Finished Samples – This is taken either in the middle of production or at the end before you make the final payment. These are parts of the finished product after a mass order chosen randomly to ensure quality control. Some people will have an inspector evaluate them. While others will be fine with photos or doing it yourself.

Ordering product Samples

Once you have found a supplier, you need to ensure that you order product samples. This should be a fairly straightforward process if they are a legitimate supplier. If you provide them with your product spec sheet and, depending on the complexity, ask for them to send you a product sample of either the product

Just be aware that ordering samples can be a process if you are getting a customized product; it’s not uncommon to have 2 or 3, or even more product samples shipped so that you can make sure that you get it right. There’s a saying that it’s better to do something right than to do it on time. That is true in this case.

Sometimes they get it right off the bat, and it only takes a week or two; other times, it takes more than a month with multiple backs and forth shipments, tweaking components or parts each time. Regardless of the time and effort in ensuring the results are well, it is better to spend time and money at this phase than later, where mistakes can become exponentially costly.

At the end of the process, you must ensure that the final sample you approve is what you want for production. Both the supplier and you will use it as a reference to compare the finished goods, so be sure you take the time to do it right. Many call this the production, reference, or golden master sample. Regardless of what you call it, ensure you do it right.

Should you pay for samples?

Mostly yes, but sometimes no; this is something that you need to negotiate with the supplier. Some suppliers will make a sample for free, and others will require you to pay for the sample production. In most cases, but only sometimes, will the supplier expect you to pay to ship.

Typically You are expected to pay a small sample fee, which can range from free plus shipping to the normal full retail price. If you are getting an item custom-made, you should expect to pay even more than retail plus shipping. Shipping is also usually by air, which is more expensive but takes 3-5 days versus more than one month. Using PayPal for the sample is typically the best way to pay due to strong buyer protection.

Regarding shipping, the factory will almost always ship the samples via air, which can get expensive, depending on the sample size. Expect to pay about 50-100 USD for small items, and for larger items, the cost can be several hundred dollars. In addition, you often need to send samples you have made for reference or have samples with revisions. This can result in several orders that are shipped and cost quite a bit.

If you think the cost of ordering a sample is high, you can negotiate to take the cost of the sample off of the purchase order. However, regardless of the high price, it’s worth spending money now to save money on any major revisions later.

How to evaluate Product Samples

When you get samples, you want to be sure that you are very thorough in evaluating the samples so that you can make sure that it meets your expectations. The best way to do this is to go through your original product spec sheet and compare every part to ensure that it matches what you described. In some cases, they may have made a sample exactly as the product spec sheet specifies, but it’s not what you expect. In that case, it likely means you need to update your product spec sheet to reflect your vision better. It is not uncommon to keep evaluating samples.

If you have specific use cases you cannot test yourself, you can work with a lab or product testing service to test your samples. It is easy to send the samples from the factory to the lab to provide this service.

Things to keep in mind about samples

For the most part, we should have covered everything, but there are a few other things to note:

Many product samples are handmade

Often, a staff member makes the samples by hand when the final product is on a production line. It is often essential to ask how your samples are being made so that you can make sure that the result is the same. You can do things by hand when you are not constrained by the time you cannot do on a production line. If this is the case, you should do a test run and have a sample shipped early in production to verify.

The final sample will be sued as a reference for production and QC

Ultimately, you should ensure that the product looks and performs exactly how you want. If not, ensure the supplier can revise and send a new one. If you are not confident that the supplier can make it exact, then it may mean you should look for a new supplier.

Remember always to send feedback to the supplier

Whether the sample is good or bad, let the supplier know exactly what you think. If it’s good, let them know. Everyone loves to hear compliments and then get ready for the mass order. If it is bad, either make changes and if they can’t, then go with a different supplier.

Let Tactical Sourcing do it for you!

Do you want our team to find great manufacturers, get quotes, and introduce you directly to great suppliers?

Our Simple Sourcing service is designed to do everything to turn your idea into a shipped product. Our services are designed to do everything to take your idea, turn it into a product, and ship it to the final destination. Cosmo can do everything from creating a product spec sheet, validation, sourcing, ordering and evaluating samples, arranging inspections, finding freight forwarders, quality assurance, negotiations, and shipping. We aim to handle every single step of your business in Vietnam for you.

If you start a new business, finding products and suppliers for your products is one of many things you need to handle. Our services are designed to handle every part of your business in China and Vietnam, so you can focus on the rest of growing your own business.

We have helped clients from Fortune 500 companies, brick-and-mortar stores, FBA sellers, and brand-new businesses. So don’t hesitate to contact us and let us know how we can help you. Email us any time at [email protected]

The Tactical Sourcing Team